Product Description

Spunbond meltblown spinning beam box for non woven fabric production line making machine

advantage

In the long-term production process, our company has continuously absorbed the opinions of on-site operators. In order to meet customers' needs for high-quality non-woven fabrics, through continuous research and improvement, our company has solved the problems of single filament coarseness, poor uniformity, bad feeling and other technologies in many spinning boxes. HHM series full panel spinning box has been developed to solve the shortcomings of uneven pressure distribution, uneven temperature and large weight deviation, so that the non-woven fabric has uniform, good transverse and longitudinal tensile capacity, thin fiber, good hand feel, no broken silk and hairless.

| Technical Parameters ( Standard Specification) of Our Nonwoven Machine |

| |

Model No. |

Gram Weight |

MaxSpeed(m/min) |

Capacity(T/Days) |

Equipment Size |

|

HH-S (single beam)

|

1.6m |

9-250 |

150 |

4-6 |

18*8*12m |

| 2.4m |

5-7 |

18*10*12m |

| 3.2m |

8-10 |

18*15*12m |

|

HH-SS (single beam)

|

1.6m |

10-120 |

350 |

8-10.5 |

45*15*12m |

| 2.4m |

10-15 |

45*18*12m |

| 3.2m |

13-20 |

45*20*12m |

|

HH-SSS (single beam)

|

1.6m |

10-100 |

550 |

12-17 |

50*15*12m |

| 2.4m |

16-21 |

50*18*12m |

| 3.2m |

24-30 |

50*20*12m |

Product Description

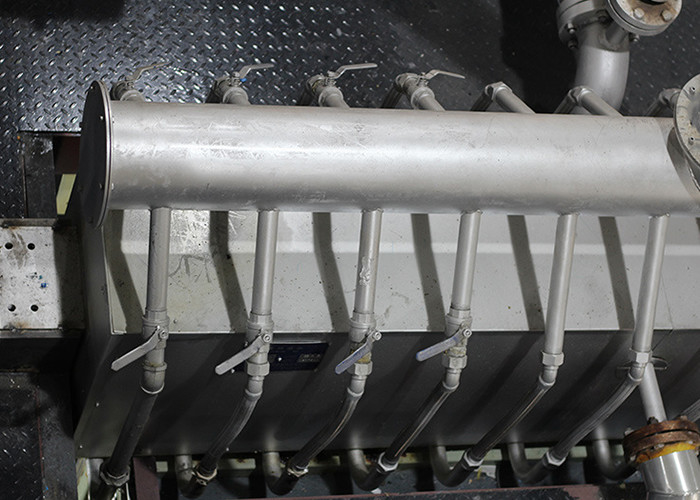

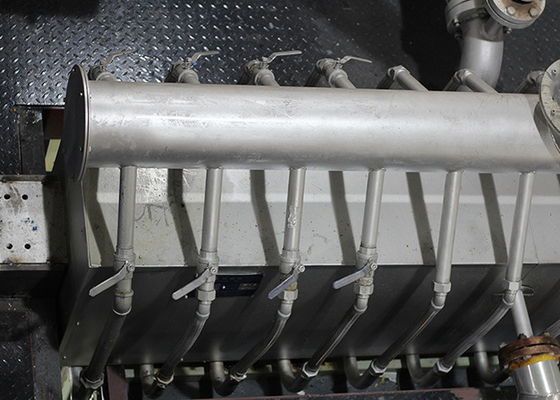

Spinning machine is one of the main parts of melt spinning machine. After the polymer melt passes through the filter, it enters the spinning box and starts spinning from each spinning position after melt distribution and heat preservation. The box is a rectangular metal box with an insulating layer. Built-in melt distributor tube (must be of the same length to avoid dead corners), pump seat and spinneret assembly (L-mounted and bottom-mounted). All parts in contact with the melt are made of stainless steel. The liquid or gas phase of biphenyl is installed in the box and heated by an electric heating rod. Each box may contain 1.2 or more square wire partss.

Parameter

| |

Length

(mm)

|

Width

(mm)

|

High

(mm)

|

Weight

(kg)

|

| 1600 |

2100 |

500 |

1300 |

2000 |

| 2400 |

2500 |

500 |

1300 |

2500 |

| 3200 |

3300 |

500 |

1300 |

3400 |

| 4800 |

5000 |

500 |

1300 |

4000 |

| Parameter above need confirm before your order , customized order also acceptable. |

Image of spinning beam box

Process Flow:

Feeding(suction, dosing, and mixing) → Melt and extruding(with recycling extruder) → Filtering → Metering → Spinning → Quenching → Air drawing → Forming → Calendering → Winding → Slitting → Product.

Advanced CNC Tools

Exhibition with customer

Shipping and packing

Machine parts with wooden box or wrapping with PE film , fixed in container keep cargo safe , for small parts or electrical compinent put in carton or wooden box ,or according with customized requirst .

FAQ:

1.How can i know your machine has good quality?

You can visit our company and we will see many machines in China,because we also have many customers from local market.

2.What is the delivery time for nonwoven machines as usual?

We need 3-6 month to make your order.

3.Will you inspect my order before shipping?

We accept SGS inspection service and buyer own inspect it,we will pay all expense for buyer visiting.

4.How is your after-sale service and warranty?

we provide 12 month warranty and free door to door engineering service in the period.

Free spare parts replacement and online technical support.

5.How long time for machine installation?

It takes 30-60 days for machine installation as usual.

6. What services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD,HKD,CHF;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese,Spanish,Russian

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!