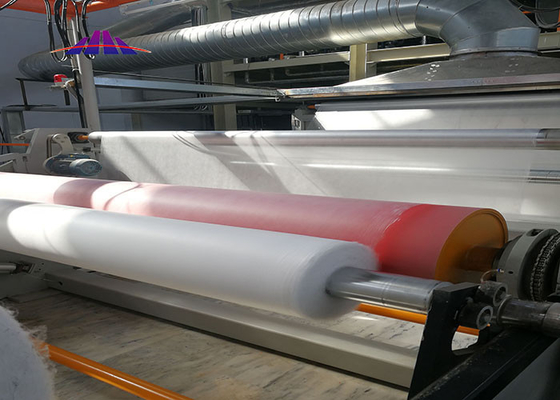

Product Description

easy operation low investment cost effective meltblown fabric production line

What ingredients are used?

PP and base metal, containing anti-oxidation, anti pilling, flame retardant and other additives.

What factors affect the quality of melt blown fabrics?

MFI and resin batch quality of polypropylene

As the best filter layer of the mask, melt blown is a very fine material with many crisscross microfibers. Using melt blown PP material with MFI up to 1500, the finer the melt blown process drawing, the better the filtration performance.

describe

The melting point of raw polypropylene is 166 ℃

Spunbonded polypropylene melt index 28-45 denier spunbonded fiber 1.8-2.5 denier

Melt blown polypropylene melt index 1300-1800 denier, melt blown fiber 1.6-4 microns

Technical Parameters

| Model |

HHM-1.6m |

HHM-2.4M |

HHM-3.2M |

| Effective Width |

1.6 M |

2.4 M |

3.2 M |

| Weight Range |

18-300 G/㎡ |

18-300 G/㎡ |

18-300 G/㎡ |

| Out put day |

2-3 Ton |

3-4 Ton |

4.5-5 Ton |

| Machine Speed |

≦70 m/min |

≦70 m/min |

≦70 m/min |

| Power Consumption |

3000º-3500º/Ton |

3000º-3500º/Ton |

3000º-3500º/Ton |

| Machine Size(L*W*H) |

18M*10M*10M |

18M*11M*10M |

18M*13M*10M |

Meltblown Making Machine Series

| Model |

Product Width

(mm)

|

GSM Range

( g / ㎡ )

|

Capacity

(kg /day )

|

Melt blown

(BFE&PFE)

|

| HHM- 1600 |

1600 |

15 - 300 |

200 - 300 |

BFE 99+

PFE 95+

|

| HHM - 2400 |

2400 |

300 - 400 |

| HHM - 3200 |

3200 |

450 - 500 |

Parts of Melt blown nonwoven fabric production line:

Main extruder→filter→Metering pump→Air heating system→Melt blown sprayer (ENKA sprayer)→Web former→Winder→Slitter

Melt blown process and technical flow chart:

Raw material →Melting→Filtering→Measureing→Air heating→Spraying→Web forming→Winding→Cutting→Final product

Meltblown non-woven fabric production line components:

Screw extruder---->filter---->metering pump---->heating system---->melt blown box (Kasen)---->netting machine---- >Rewind

(1) Receiving networked device:

Line speed: up to 50m/min

Meltblown receiving adjustment range: 200mm

Installation form: It can be moved horizontally, which is convenient for installation, debugging and maintenance

Driving rate: 1.1KW

(2) Suction net fan:

Power: 75KW,

4. Hot air heating system

(1) Atlas air compressor

Boost pressure: 0.7MPa

Power: 120KW~200KW

(2) Air heater

Heating power: 220KW-240KW

Material of tank and pipeline: stainless steel 304

Insulation form: stainless steel seal outside the insulation layer

5. Electret system.

6. Rack platform device:

Steel structure, easy to disassemble, firm and reliable, including stairs, etc.

7. Die head heating power: about 70kw

8. Electrical control box

High precisely CNC center

Exhibition Show

Packing & shipping

Electrical parts small parts each numbered put in carton or wooden box , large scale machine will nude wrarping with PE film fixed in container keep cargo safe .

Our Service

1.Pre-sale Service

Employees have a special sense of responsibility and excellent teamwork spirit, so the machine adopts unique and outstanding components, which meet the highest standards of the nonwoven industry.

With the support of modern technology, to provide all customers with the best solution machinery Claim.

2.After-sales Service

Our customer service can answer inquiries.

We only believe that: the best machine with innovative ideas and high-quality after-sales service: "will meet your special requirements."

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!